Hydraulic Power Units

Comprehensive Solution Competence

Hydraulic Power Units – Engineered for Every Application

We specialize in the design and manufacturing of hydraulic power units and systems for a wide range of industrial applications. As one of India’s largest system integrator for Rexroth Bosch in hydraulic and automation, we bring unmatched technical expertise and integration capability to every project.

With over 40 years of experience across diverse industries, we offer both standard and fully customized hydraulic solutions tailored to your specific requirements. From compact units to large-scale systems with tank volumes up to 2000 liters, our energy-efficient, low-noise, and reliable power units are built to perform across diverse industries.

Project Planning, Commissioning & After-Sales Service

From Start to Finish – All in One Hand

Save valuable time and resources: we take care of the complete lifecycle of your hydraulic power unit — from project planning and engineering to assembly, commissioning, and after-sales service — wherever you need it.

Working in a customer-focused and solution-driven manner, we design and deliver your hydraulic system to precisely match your operational needs and boundary conditions, ensuring seamless performance and total peace of mind.

Your benefit: Our expertise – Powerful, intelligent, future-proof

Our power units portfolio

Energy-efficient, quiet and safe: You specify the general conditions, we design and manufacture the perfectly fitting hydraulic power unit – from compact series units to project-specific systems with up to 75,000 litres tank capacity.

| Compact S | Medium M / Large L | Extra Large XL |

|---|---|---|

|

|

|

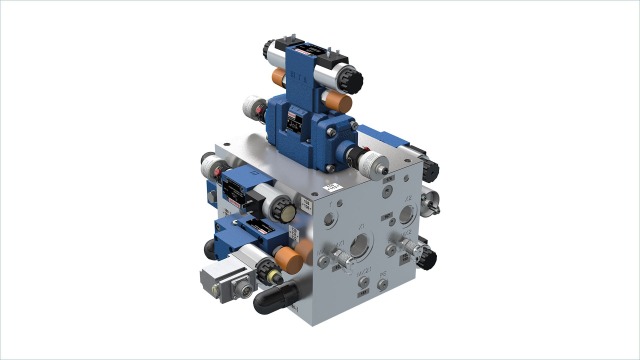

We design and manufacture custom manifold blocks to meet your exact specifications

Multi-station manifolds are the basic element for ready-to-connect control blocks in vertical stacking design with 1 to 10 stations. On each station, highly compact hydraulic controls can be built using vertically stackable sandwich plate valves in conjunction with on/off valves, proportional valves, high-response valves or servo valves. configurator.

Modular plate systems are modular block systems for set-up of controls in a compact construction, ready for connection. They can be realized individually from different modules and additional vertical stackings.

Standardized functional modules include ready-assembled and tested units for general hydraulic functions such as accumulator shut-off blocks or pump protection blocks , special industry functions such as press modules , press brakes, or functional safety blocks. We also offer individual, customer-specific control blocks on request.

Shut-off blocks (ABZSS, VAW) are used for safeguarding, shutting off and relieving hydraulic accumulators in accordance with Pressure Equipment Directive . They can be used with manual and electrical relief at pressures up to 350 bar. The accumulator blocks can also be configured including the accumulator as an accumulator assembly .

Click to explore Compact or Standard hydraulic power units

Based on an aluminum tank, The drive power reaches from 0.37 kW to 7.5 kW with a tank capacity of 20 to 60l and an oscillating volume of approx. 11l. By means of a configurator, these power units can be individually customized and constructed for the application at hand.

small power units

medium-size power units

Drive units with a tank volume greater than 1000 l and, in most cases, several motor pump units, as well as further modules (accumulator module, filter module, circulating module).

large power units

Small power units CytroPac

- Component series 1X

- Tank size 20 l

- Maximum operating pressure 240 bar

- Power 1.5 … 4 kW

Medium-size power unit CytroBox

- Component series 1X

- Maximum operating pressure 315 bar

- Maximum flow 160 l/min

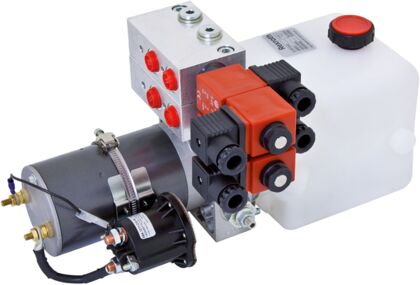

- For hydraulic dock leveller applications with single or double acting cylinders

- AC motors up to 2200 W

- Flow up to 4.8 l/min (at 1500 rpm)

- Peak pressure up to 230 bar

- For clamping operations in machine tools

- AC motors up to 2200 W

- Flow up to 20.7 l/min (at 2800 rpm)

- Peak pressure up to 270 bar

- Smallest overall dimensions

- DC motors up to 2200 W

- AC motors up to 1100 W

- Flow up to 2.25 l/min (at 1500 rpm)

- Peak pressure up to 230 bar

- For standard and complex hydraulic circuits and lifting applications

- DC motors up to 3000 W

- AC motors up to 4000 W

- Flow up to 14.8 l/min (at 1500 rpm)

- Peak pressure up to 350 bar